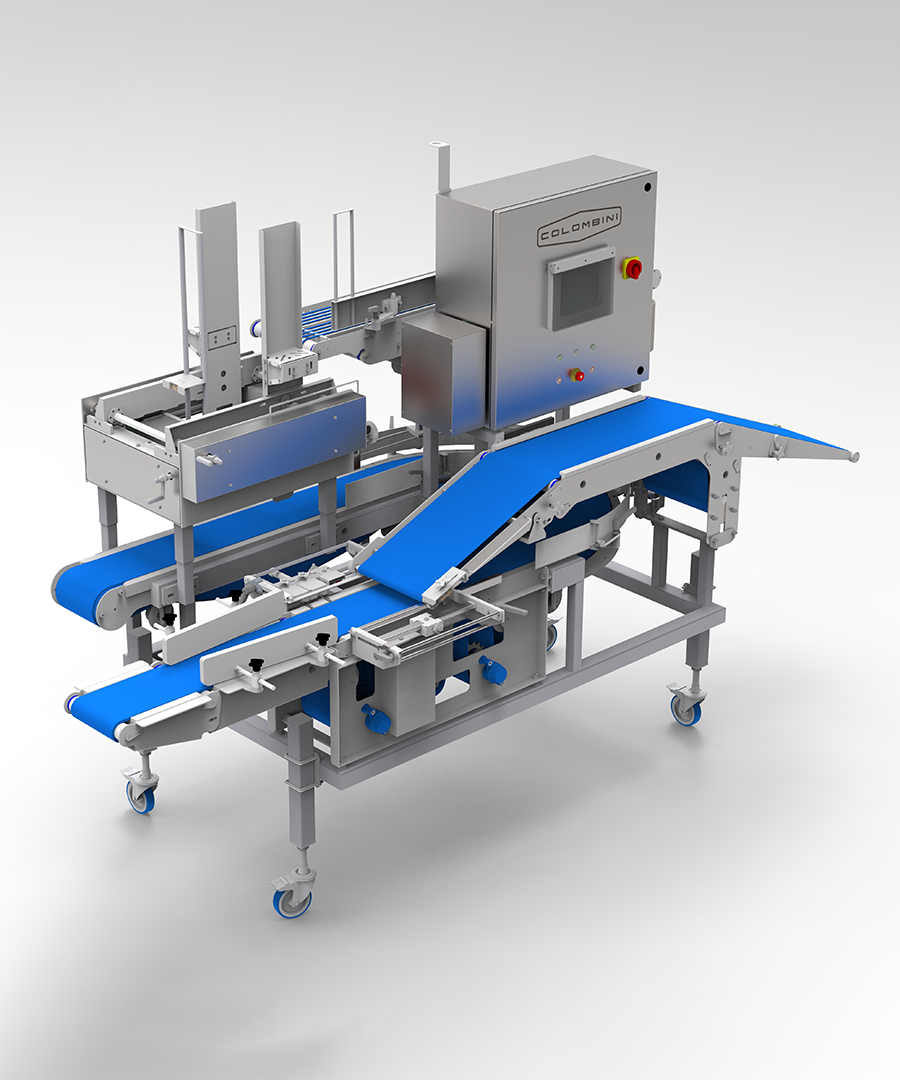

RVN-Tray dispenser with burger loading

The RVN is an automated tray dispenser designed for the efficient and hygienic handling of hamburger and ground meat, designed for the food processing industry. It is specifically developed for dispensing polystyrene and PET trays containing meat or vegetable products, ensuring perfect synchronization between product and carrier. The system enables precise loading of single, double or multiple burgers, as well as portions of ground meat, adapting to a wide range of production requirements.

The machine is equipped with an electronically controlled four-spiral system to handle different formats with an operating speed of up to 50 trays per minute. The tray magazine is automatic loading, optimized to maintain high production rates without the need for frequent intervention. The belt conveyor line ensures proper positioning of trays for loading, while the single-component filling belt, made for direct food contact, is designed to ensure hygiene and simplicity in daily cleaning operations.

The motors and gearboxes used are made of alloy and stainless steel with IP69K protection, resistant to intensive working conditions and frequent sanitization. Constant availability of spare parts ensures operational continuity, reducing downtime. Entirely designed and built to meet the quality standards of the food industry, the RVN system is a reliable, high-performance solution for automation in tray distribution.

Spiralizing sausages

The BS400 bandsaw is designed for high performance, safety and hygiene in the food industry, ideal for butcher shops, laboratories, supermarkets and processing plants.

Made of AISI stainless steel, the BS400 offers corrosion resistance and long life even in environments subject to frequent washing. The materials chosen comply with food industry sanitation regulations.

The machine body is designed for easy daily cleaning, with a quick opening system and integrated cleaning device. The compact design allows easy installation even in small spaces.

The anti-friction blade guide ensures precise cuts, while the adjustable blade tensioner maintains constant tension, prolonging blade life. The thickness stop ensures uniform and repeatable slices.

Integrated lifting handles and front wheels with brakes allow easy handling while maintaining stability during use.

Equipped with safety microswitch on the inspection door and emergency button, the BS400 ensures safety. The ventilated motor with thermal protection ensures reliability even under heavy loads.

Reliable, easy to use and built with high quality materials, the BS400 sawing machine is the ideal professional solution for those seeking efficiency, safety and hygiene in food processing.

Tray dispensers

DVA – Autonomous Tray Dispenser

The DVA model is a compact and versatile solution equipped with an electronically controlled four-spiral system that ensures distribution precision. Designed to operate autonomously, it is ideal for flexible applications thanks to its fast format adjustment. It can reach a maximum speed of 50 trays per minute, making it an efficient choice for production lines that require continuity and operational simplicity.

DVM – Tray Dispenser with Warehouse

The DVM integrates the DVA system with an automatic loading warehouse, optimizing efficiency in high-intensity production settings. This configuration reduces setup time and ensures a continuous flow of ready-to-use trays. It is an ideal solution for plants that require extended autonomy and minimal operator supervision, improving load handling and overall productivity.

DVP – Monoform Pneumatic Distributor

The DVP is a four-rotor system designed for simple and reliable distribution of single-format trays. With its pneumatic operation and proven mechanics, it is perfectly suited for standard lines where consistency and repeatability are required. Its compact design allows it to be integrated into small spaces with minimal maintenance and easy operation.

Special Tray Dispensers

For more specific needs, Colombini Srl offers customized solutions for the distribution of trays in different formats and materials. Configurations can be single or multiple and are custom developed to fit the requirements of the production line. All equipment is entirely designed, manufactured and distributed by Colombini Srl, in full compliance with sanitary regulations, guaranteeing quality, reliability and optimal integration into food processes.

Portioned lines

Colombini Srl specializes in the design and manufacture of automated lines for portioning and trapping of meat and vegetable-based food products. Thanks to a consolidated experience in the field and the use of advanced technologies, the company proposes tailor-made solutions capable of optimizing the entire production process, improving operational speed, presentation quality and food safety of the finished product.

The lines developed by Colombini are designed to ensure maximum hygiene and traceability, integrating precise portioning systems and efficient and reliable tray placing modules. Correct labeling, compliance with regulations, and the ability to adapt each line to the specific type of product-whether fresh meat, preparations, or vegetables-make each system highly customizable, flexible, and easily integrated into existing industrial settings.

The adoption of modern portioning and packaging solutions not only enables increased productivity but also raises the quality standards of the supply. The proper training of personnel and the adoption of strict sanitary procedures are central elements for the efficient and safe operation of the lines. Colombini Srl thus confirms itself as a reliable partner for companies in the food sector that intend to invest in automation, control and quality.